Company profile Krones Middle East Africa FZCO

Krones Middle East Africa (MEA) is a sales and service facility for clients in MEA, with headquarters in Dubai and local offices in several countries in the region.

As a supplier of complete systems, Krones is a world leader in providing beverage bottlers and food producers with individual machines and complete production lines. Krones systems cover every single production step - from product and container manufacture, through filling and packaging, to material flow, digital solutions and container recycling.

Krones subsidiaries

Process technology

The basic steps for processing beverages and dairy products may be similar, but each type of product has its own unique characteristics. And each type of product must go through a set of defined steps to meet strict regulatory and safety requirements.

A dedicated team of experts on site is committed to providing the best processing technology with simple, efficient and tailor-made solutions.

Do you want your products to stand out from the crowd? Then you should rely on process technology that keeps pace with your ideas and inspires your imagination instead of limiting it. Because whether it's a classic or a new creation - we'll provide you with a solution that does one hundred percent justice to your soft drinks and your production.

Do you want your products to stand out from the crowd? Then you should rely on process technology that keeps pace with your ideas and inspires your imagination instead of limiting it. Because whether it's a classic or a new creation - we'll provide you with a solution that does one hundred percent justice to your soft drinks and your production.

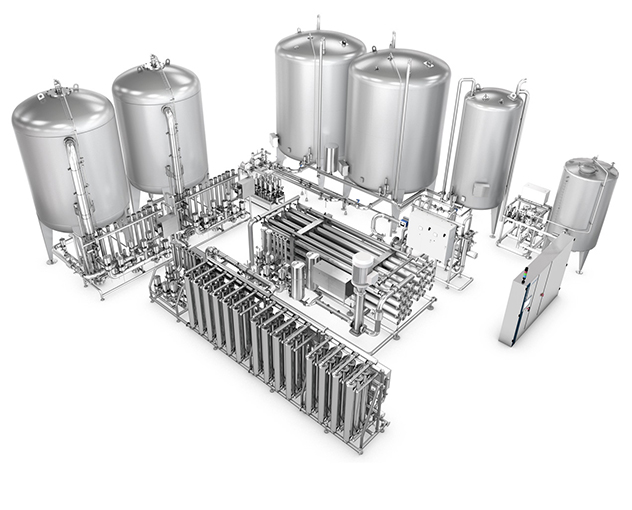

Language may reach its limits when it comes to water, but Krones' process technology does not. Whether as brewing water, process water or as a raw material for soft drinks, juice or tea: with Krones process technology, you give your water precisely the character that goes down best with your customers or your production.

Language may reach its limits when it comes to water, but Krones' process technology does not. Whether as brewing water, process water or as a raw material for soft drinks, juice or tea: with Krones process technology, you give your water precisely the character that goes down best with your customers or your production.

In beverage production, beverages containing fruit pieces and fruit fibres prove to be extremely sensitive and require appropriate treatment. Processes for preservation and safe hygienic processes are essential factors in product production. With our process technology solutions, we offer the necessary equipment to ensure high product quality and to preserve the taste of fruit juices, smoothies and fruit nectars.

In beverage production, beverages containing fruit pieces and fruit fibres prove to be extremely sensitive and require appropriate treatment. Processes for preservation and safe hygienic processes are essential factors in product production. With our process technology solutions, we offer the necessary equipment to ensure high product quality and to preserve the taste of fruit juices, smoothies and fruit nectars.

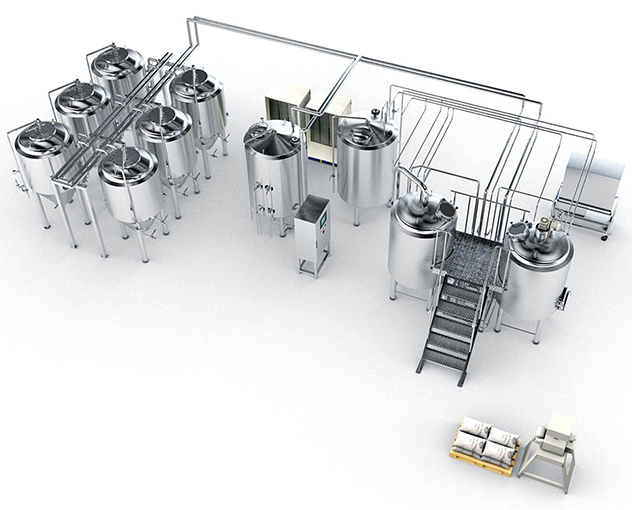

The lines from Krones Process Technology do their utmost to ensure that your customers are rewarded with a wonderfully enjoyable experience. Whether you are filling ESL milk, refining dairy beverages with fruit particles or cereals, whether your products demand special hygiene, gentle handling or even both: Our systems master every challenge that awaits process technology in dairies and the dairy industry.

The lines from Krones Process Technology do their utmost to ensure that your customers are rewarded with a wonderfully enjoyable experience. Whether you are filling ESL milk, refining dairy beverages with fruit particles or cereals, whether your products demand special hygiene, gentle handling or even both: Our systems master every challenge that awaits process technology in dairies and the dairy industry.

With proven technology and young ideas, Steinecker Brewing Technology enriches every step of the production process - from milling to filtration, from raw material to product ready for sale. Brewing special beers, increasing output, reducing energy consumption? You decide where the journey should go. And we supply you with the brewing technology that will get you safely to your destination.

With proven technology and young ideas, Steinecker Brewing Technology enriches every step of the production process - from milling to filtration, from raw material to product ready for sale. Brewing special beers, increasing output, reducing energy consumption? You decide where the journey should go. And we supply you with the brewing technology that will get you safely to your destination.

Do you want a design that makes your bottle stand out from the crowd? Or do you want to set new records for material savings with professional lightweighting? Whatever your bottle design requirements, Krones' design professionals are guaranteed to find the right shape for your ideas and goals. Our dedicated bottle designers are based in Dubai and serve clients with in-depth market knowledge. We are able to create prototypes of your future bottle thanks to our local rapid prototyping and 3D printing equipment.

Do you want a design that makes your bottle stand out from the crowd? Or do you want to set new records for material savings with professional lightweighting? Whatever your bottle design requirements, Krones' design professionals are guaranteed to find the right shape for your ideas and goals. Our dedicated bottle designers are based in Dubai and serve clients with in-depth market knowledge. We are able to create prototypes of your future bottle thanks to our local rapid prototyping and 3D printing equipment.

A Formula One car that saves fuel? Unimaginable on the race track, no problem on a Krones PET line. The stretch blow-moulding machines in the Contiform 3 series transform a preform into a PET bottle in a speedy 1.6 seconds. With an output of 2,250 bottles per blow-moulding station, they achieve an output of 82,000 bottles in PET bottle production. But this speed leaves no traces in the consumption balance sheet. Because new developments at targeted points, such as the oven, stretching system and air recycling, curb the appetite for energy and compressed air - and even make the Contiform 3 the most economical Krones stretch blow-moulding machine of all time.

A Formula One car that saves fuel? Unimaginable on the race track, no problem on a Krones PET line. The stretch blow-moulding machines in the Contiform 3 series transform a preform into a PET bottle in a speedy 1.6 seconds. With an output of 2,250 bottles per blow-moulding station, they achieve an output of 82,000 bottles in PET bottle production. But this speed leaves no traces in the consumption balance sheet. Because new developments at targeted points, such as the oven, stretching system and air recycling, curb the appetite for energy and compressed air - and even make the Contiform 3 the most economical Krones stretch blow-moulding machine of all time.

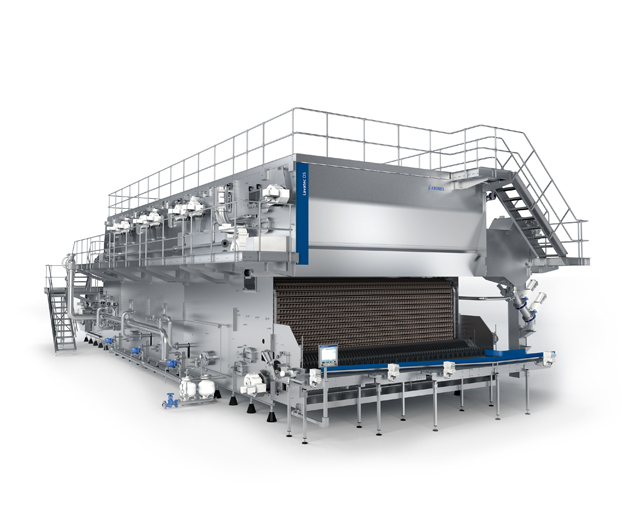

It's not a job for beginners or light shoulders. Because bottle washing doesn't allow any mistakes in terms of hygiene and product safety. And at the same time, it demands economical use of the precious resource of water. The bottle washing machines of the Lavatec series show how these two extremes can be reconciled. Whether confined space or high output, easily soluble labels or tricky cleaning tasks, multi-talented all-rounder or cost-effective basic system: each Krones bottle washer is designed for different requirements and is an experienced specialist in its field.

It's not a job for beginners or light shoulders. Because bottle washing doesn't allow any mistakes in terms of hygiene and product safety. And at the same time, it demands economical use of the precious resource of water. The bottle washing machines of the Lavatec series show how these two extremes can be reconciled. Whether confined space or high output, easily soluble labels or tricky cleaning tasks, multi-talented all-rounder or cost-effective basic system: each Krones bottle washer is designed for different requirements and is an experienced specialist in its field.

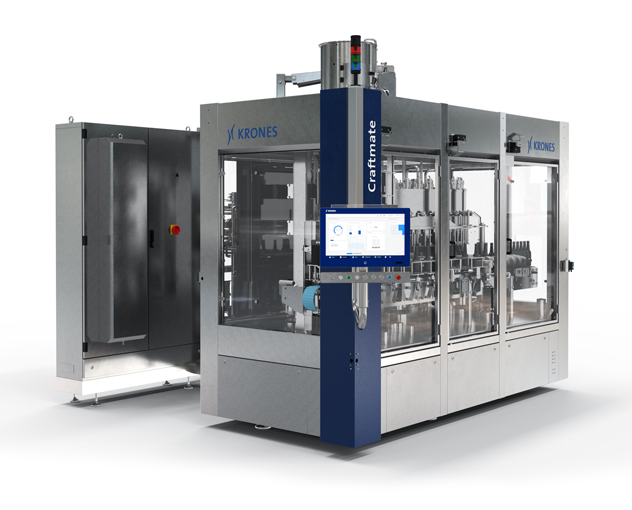

Which filling process does your product prefer? Cold, hot or aseptic? And what do you want from your filling line? That it fills with a lot of precision and little foam? That it brings your product gently into the bottle and protects it from oxygen? That it remains flexible for different formats and also knows how to handle lightweighting bottles? Whichever and however many of these points are important to you for your bottling - among Krones' bottling lines, you'll find the right technology for every taste.

Which filling process does your product prefer? Cold, hot or aseptic? And what do you want from your filling line? That it fills with a lot of precision and little foam? That it brings your product gently into the bottle and protects it from oxygen? That it remains flexible for different formats and also knows how to handle lightweighting bottles? Whichever and however many of these points are important to you for your bottling - among Krones' bottling lines, you'll find the right technology for every taste.

Is the can clean? Does the label fit correctly? And is the fill level in the bottle correct? With inspectors from Krones, every one of these questions can be answered with a resounding "yes". Because the inspectors perform a conscientious pack, can or bottle inspection for you - and unerringly eject those products that do not meet your quality standards.

Is the can clean? Does the label fit correctly? And is the fill level in the bottle correct? With inspectors from Krones, every one of these questions can be answered with a resounding "yes". Because the inspectors perform a conscientious pack, can or bottle inspection for you - and unerringly eject those products that do not meet your quality standards.

A shelf full of possibilities, the blink of an eye - and the die is cast. As a producer of consumer goods, you know that consumers decide on a product in a fraction of a second. With labellers from Krones, you can be sure that your product will convince them at first glance. Whether hot glue, cold glue, self-adhesive labels or sleeves: our labelling technology easily masters every equipment variant - and if you like, even all of them together on one machine.

A shelf full of possibilities, the blink of an eye - and the die is cast. As a producer of consumer goods, you know that consumers decide on a product in a fraction of a second. With labellers from Krones, you can be sure that your product will convince them at first glance. Whether hot glue, cold glue, self-adhesive labels or sleeves: our labelling technology easily masters every equipment variant - and if you like, even all of them together on one machine.

It's quite clear: the performance of a beverage line depends on the individual components. And on all of them. Because even the fastest filling or packaging machines can only give their all if everything is right between them, too. That's why the Krones conveyors do much more than just conveyor sections: they control the entire logistics within a line. Through intelligent distribution, steering and buffering, they create harmony between the individual line components - and thus point the way to safe and efficient production.

It's quite clear: the performance of a beverage line depends on the individual components. And on all of them. Because even the fastest filling or packaging machines can only give their all if everything is right between them, too. That's why the Krones conveyors do much more than just conveyor sections: they control the entire logistics within a line. Through intelligent distribution, steering and buffering, they create harmony between the individual line components - and thus point the way to safe and efficient production.

With Krones' systems for product handling and container handling, you get the temperature factor on your side. Because the pasteurisers, warmers and coolers create an individual climate for each product, precisely matched to the respective processing step: with a Krones product treatment and container handling system, ...

- pasteurise sensitive beverages gently and reliably.

- gently recool hot-filled products.

- heat cold-filled containers for the packing and labelling process.

With Krones' systems for product handling and container handling, you get the temperature factor on your side. Because the pasteurisers, warmers and coolers create an individual climate for each product, precisely matched to the respective processing step: with a Krones product treatment and container handling system, ...

- pasteurise sensitive beverages gently and reliably.

- gently recool hot-filled products.

- heat cold-filled containers for the packing and labelling process.

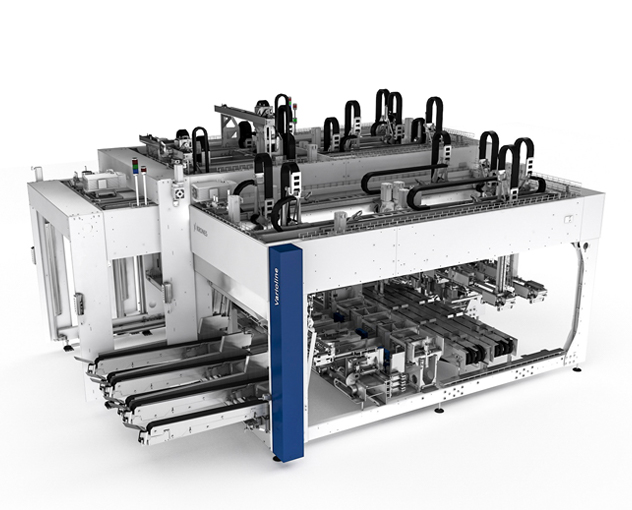

As a manufacturer of consumer goods, you know that there are countless ways of packaging products. Krones' packaging lines are capable of handling the most varied types of primary and secondary packaging. And even if they have already been in operation for several years, they can easily be converted to other types of packaging. For you, this means one thing above all: that you can face future developments with confidence. Because wherever the journey takes you, your packaging machines will definitely be on board.

As a manufacturer of consumer goods, you know that there are countless ways of packaging products. Krones' packaging lines are capable of handling the most varied types of primary and secondary packaging. And even if they have already been in operation for several years, they can easily be converted to other types of packaging. For you, this means one thing above all: that you can face future developments with confidence. Because wherever the journey takes you, your packaging machines will definitely be on board.

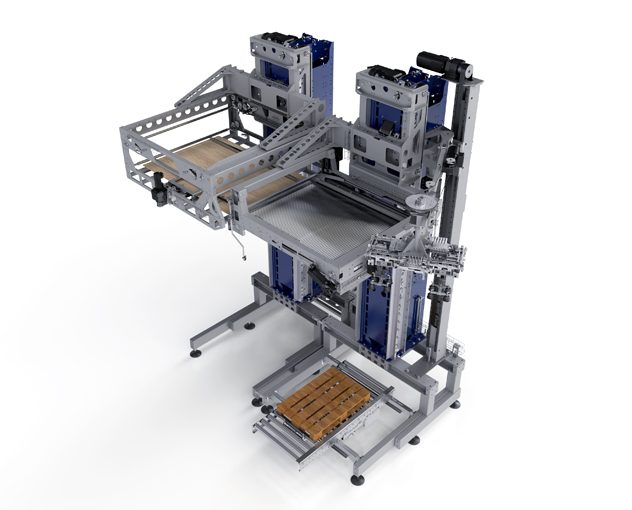

What plays the biggest role in palletising: performance or precision? Good news for all those who can't (or don't want to) decide: Krones' palletisers work with millimetre precision, stacking up to 600 layers an hour. To ensure that your products feel well taken care of at this speed, each robot is individually configured - from the motion sequences to the gripping tools. No matter whether you are processing disposable containers or reusable crates: Together with our product specialists, you will find the ideal palletiser for your production.

What plays the biggest role in palletising: performance or precision? Good news for all those who can't (or don't want to) decide: Krones' palletisers work with millimetre precision, stacking up to 600 layers an hour. To ensure that your products feel well taken care of at this speed, each robot is individually configured - from the motion sequences to the gripping tools. No matter whether you are processing disposable containers or reusable crates: Together with our product specialists, you will find the ideal palletiser for your production.

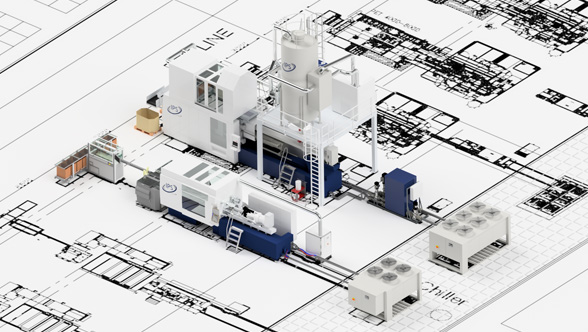

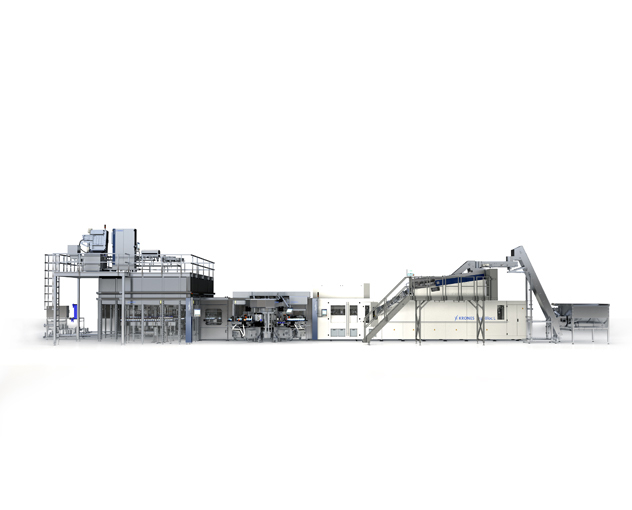

Blocks are the spearhead of line technology. This is because they merge the functions of several machines into a single, compact unit. The result is a highly automated overall package in which the individual process steps link up seamlessly - without buffers, without detours, without time losses. Whether wet end or dry end, aseptic or standard production, multi-format or highly specialised line: the Krones block technology adapts individually to your products, your containers and your requirements.

Blocks are the spearhead of line technology. This is because they merge the functions of several machines into a single, compact unit. The result is a highly automated overall package in which the individual process steps link up seamlessly - without buffers, without detours, without time losses. Whether wet end or dry end, aseptic or standard production, multi-format or highly specialised line: the Krones block technology adapts individually to your products, your containers and your requirements.

Intralogistics as it should be

Short distances, lean processes and agile material flows that flexibly adapt to production and dispatch. In intralogistics, absolute efficiency is the order of the day. In order to do full justice to this, we leave nothing to chance when planning and implementing your intralogistics project: we think our way into your products and processes, research existing material flows and systematically search for previously unused potential. The findings from this form the objective basis on which we develop the master plan for your intralogistics. If you wish, we can advise you on the selection of technical equipment and supervise the entire construction process up to commissioning. In the end, we hand over a turnkey warehouse or distribution centre whose processes, technology and software fit seamlessly into your operations.

Achieving peak performance together

What do you expect from a partner at your side? That he knows exactly what your wishes and needs are and has the right answers at the ready? That you understand each other blindly and can always rely on each other? That together you form a strong team that achieves top performance? Krones Lifecycle Service meets all these requirements. Especially when you consider the local technical support and the dedicated service technicians in the countries of the Middle East and North Africa.

Complete solutions from a single source

Beverages and food are our world - and have been for over sixty years. Once started as a labelling machine workshop, we have developed into an all-round partner for the industry. Why? Because our heart beats for technology and we are driven by a clear goal: We want to provide our customers with everything they need to succeed.

Better performance with training from the Krones Academy

Exchanging experience and imparting knowledge about Krones technology - worldwide and always precisely tailored to you and your framework conditions. This is a brief description of our training concept. The aim is always to raise the performance of your line to a new level, together with you.

Just one click away

The future of service support is becoming increasingly digital. But what is still a vision of the future for some is already corporate reality at Krones. For ordering spare parts, upgrades, components, training, service technicians and used machines, the Krones.shop has already been the digital platform for the food and beverage sector for five years. With a portfolio of now almost five million products, the e-shop is constantly evolving and comes up with a number of new features.